Manufacturing business tips: how to find more resistant and durable materials

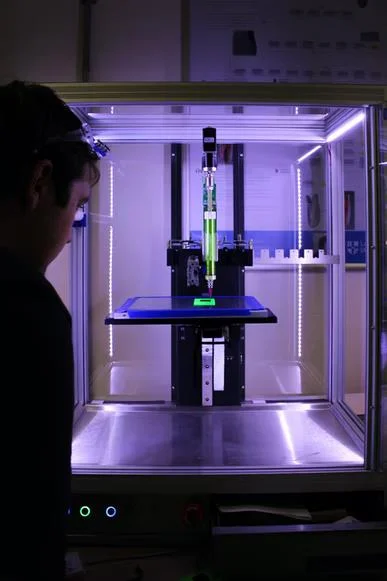

When it comes to manufacturing, many different materials can be used. Finding the right material for your product is one of the most important parts of the process. The wrong choice could lead to a poor quality product, reduced durability, and decreased resistance to wear and tear. That’s why we want you to find out about some new materials that will help you create products that last longer than ever before!

Materials can be resilient or non-resilient

Resilient materials can withstand a force and return to their original condition. These types of materials, such as vespel sp 1, are usually used in factories because they help with production. The more resilient the material, the better it is for use during manufacturing processes that require manual labor or heavy machinery such as drills and presses. Some companies will even hire companies dedicated to finding new durable materials so their product line remains fresh and innovative year after year.

Non-resilient materials cannot return to an original state if bent or pressed upon by some type of pressure, these may be considered unsafe depending on how much weight they were able to hold before bending under pressure (known as yield strength). Yield strength is very important when deciding between buying different types of metal prototypes since the strength of the metal is what determines whether or not it will hold up in a production environment. Metals with high yield strengths are more likely to be used for manufacturing tools and parts because they can withstand heavy use over time without breaking.

Know what you want to create

Consider what you want to create and why you want to create it. That will help guide your search for the right materials to use in manufacturing. If you’re creating a new product, talk with people who have experience working with those specific types of substances and ask them what they recommend as far as which material is strongest or most durable or resists corrosion best.

Consider how the material will be used. If you’re creating a product that’s going to be heavily used, such as an industrial tool or machine part, it makes more sense to use a strong and durable metal than one with extreme flexibility (which is better suited for things like clothing).

Get in touch with suppliers

After you have identified your supplier, it is time to get in touch with them. You can use the internet or other marketing strategies to do this, but that should only be the first step. This will help you find suppliers who can provide what you need for maximum durability and resistance of materials used in manufacturing processes.

It’s also important not just to look for an initial phone call – make sure that they offer more than one type of material so that if something goes wrong, at least there is another option available! That way, even if something does go south during production because of poor quality raw materials being used by your manufacturer, at least you know you tried everything possible beforehand!

Always keep your eyes peeled

During the first phone call, a supplier should be able to give you some information about their materials and what they offer. While this is good news on its own, it’s always important to keep your eyes peeled for more – after all, sometimes things can go wrong! This means that going through multiple suppliers or at least checking different options before making a final decision is extremely helpful as well. Not only do you get support from many sources but if something goes south with one of them there are other alternatives available! Keeping an eye out during negotiations will help make sure that even if everything else fails, you have identified new possibilities in advance so when push comes to shove you won’t be caught off guard by anything.

Be willing to pay a bit more

You mustn’t expect too much from your supplier, but at the same time, it’s also good for them if they can provide materials that help their customers save money in other areas like transportation or storage costs, etc. This means that sometimes paying a little extra might be beneficial – after all, this goes both ways! If there isn’t any additional cost involved with better quality raw materials because of negotiated prices and contracts, then taking advantage of what’s available will make sure everything goes according to plan while still saving some cash on secondary expenditures.

Ask about the product’s warranty

Once you have finalized your negotiations and received samples of the material, it is time to test them out. Depending on what kind of contract was signed for this order, there will be different requirements that must be met; but in most cases, testing might require special equipment or tools designed specifically for each type of manufacturing process. This means that getting these items can sometimes take a bit longer than anticipated – especially if they are not readily available at local shops! Asking about the warranty period during negotiations should prevent some issues from arising once everything has been tested because knowing how long you need to wait until something goes wrong with your product allows you to plan accordingly without too much trouble.

Don’t be afraid to ask for a discount

Although this may seem counter-intuitive, asking for a discount can help you reduce costs in the long run. When negotiating prices with your supplier before placing an order, try suggesting that they give you some kind of coupon or rebate once everything is done because it’s good for business on both sides! This way, if something does go wrong during production and there are problems with materials used by manufacturers, at least all parties involved know what needs to happen so everyone benefits from any discounts given! That means customers will still get quality products while suppliers maintain their reputation as experts who provide high-quality services – especially when dealing with durable and resistant materials like those mentioned here today.

By finding more resistant and durable materials, you can have a stronger impact on your manufacturing business. The key is understanding different methods for how to find these types of materials so that you can start using them immediately. If this process seems too complicated or overwhelming, consider working with someone who specializes in helping businesses identify the best type of material for their needs.