It is difficult to imagine how difficult the work of historians would have been if the ancient papyri had not fallen into their hands. From the ruins of temples and household items found in tombs alone, you cannot make up a picture of the past. And this writing material itself could be completely different – perishable, or excessively expensive, or rare.

But the papyrus did humanity an excellent service, preserving information about the ancient world for millennia. True, it was not without ambiguities and omissions here, too – some of them are associated precisely with the process of transforming the plant of the Nile swamps into papyrus scrolls.

What was ancient papyrus

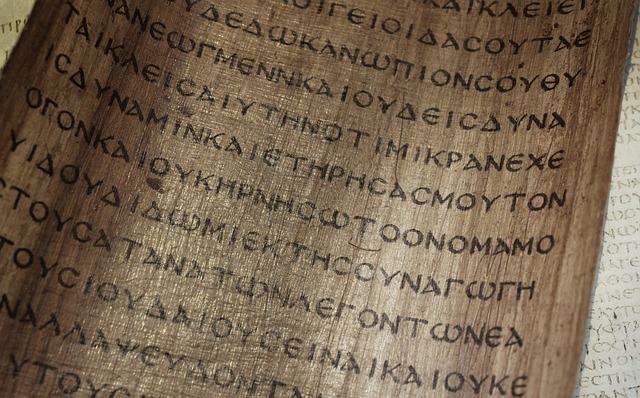

Since we are talking about antiquity, when there were no effective medicines, no more or less convenient means of transport, or even money in the usual sense of the word, a rather unflattering idea is formed about the material for recordings. The imagination draws something like wet clay, on which they scratch with a wedge-shaped stick or hastily obtained birch bark, suitable for marking dashes-words on it.

But with papyrus – even though a rather venerable age distinguishes its history – everything is not so: its production technology deserves a separate study. It was a rather delicate work that required a conscious approach and knowledge of the material: otherwise, the product would be of poor quality and would indeed not have survived to this day.

Papyrus began its history in Ancient Egypt, later spreading throughout the ancient world. In very ancient times, the papyrus plant was probably a symbol of Egypt. It was called in those days, of course, differently: the word “papyrus” is of Greek origin, it gave birth to many terms, including “paper” in English, French, German and other languages. The words “Wadj”, “Tjufyi”, “Djet” this is how papyrus was called in ancient Egypt.

Of course, this sedge herb could not grow in the desert, papyrus was mined in swampy soils along the Nile banks, and this activity was seasonal and was confined to the floods of the great river. In addition to being used as a writing material, papyrus was also used as a building material – for building boats and arranging houses. Ropes and mats were woven from the stems of these plants; papyrus in different species could become part of the diet of animals or even humans; the ash of this plant was added to ancient medicinal drugs.

The oldest surviving papyri were discovered in a tomb of the 1st dynasty; the burial dates back to about 2850 BC. Since then, this material has served humanity for several thousand years, after which it was supplanted by parchment and forgotten for several centuries.

Papyrus production technology

Papyrus is a perennial plant whose stems, about the thickness of a human hand, can reach 4 to 6 meters in height. It does not need much – only constantly moistened soil. Papyrus does not suffer from diseases; insects do not eat it, it is not of great interest to animals. There is absolutely no data on how the extraction of papyrus was carried out in Ancient Egypt.

Some assumptions are based only on the fact that the documents were used widely and related to various aspects of life, including minor business matters. Therefore, there was no shortage of this writing material.

In ancient times – this is known from the writings of Greek and Roman historians – the most considerable plantations of papyrus were the Fayum oasis and the suburbs of Alexandria in the Nile delta region. We are talking about thousands of square kilometres, hundreds of workers who worked there, and the procedure for collecting papyrus and processing it was probably carefully debugged over the centuries of its existence.

Historians have practically no information about the ancient technology for the production of papyrus scrolls – information is drawn from Pliny’s work entitled “Natural History”, but the Roman, when describing the process, admits apparent contradictions and is not always consistent. Therefore, scientists question the reliability of his testimony. However, in the absence of other sources of information, Pliny’s story cannot be ignored.

The papyrus was collected by pulling out the stem from the root; otherwise, the plant fragments remaining in the soil would lead to decay processes. The upper, outer part of the stem was removed, the core was cut into long thin strips and laid on a large flat surface so that the edges only slightly overlapped one another.

Each layer was abundantly moistened with water (according to Pliny – from the Nile), beat off with a hammer, added glue, beat off again. After that, the papyrus was left to dry under pressure.

The width of the sheet ranged from 15 to 47 centimetres; the finished papyrus leaf was rolled into a scroll. First, they wrote on the inside of the scroll, and only when there was a lack of space did they move to the outside. Sometimes what was written earlier was erased, and the papyrus was reused – according to some historians, this indirectly confirms the relatively high papyrus cost. In contrast, others attribute this habit to the natural economy of material for a person.

Recreating the technology of making papyri today

For some reason, not a single ancient Egyptian monument left information about how much and how papyrus was made and who was in charge of this production. But images of papyrus can be found on the walls of ancient temples – in the form of hieroglyphs. And an essential element of many Egyptian buildings – columns – was also built in papyrus stems.

The oldest of the documents created thanks to this material is the “Prisse Papyrus”, dating from the 20th – 18th centuries. BC. The preservation of the papyrus over such a long time is difficult to explain by the climate of Egypt alone, undoubtedly highly favourable for many of the ancient materials.

How quickly the scroll lost its flexibility and crumbled to dust depended on the composition of the papyrus and possibly on the technology of its manufacture, including the ingredients for the adhesive.

The papyrus could be of different varieties, on which the cost of the finished scroll also depended – this is also known from the work of Pliny. In ancient times, up to a million scrolls were made a year – the production of papyrus was carried out not only on the African continent but also in Sicily, where their plantations were created.

Papyri were finally superseded by another writing material – parchment – at the beginning of the second millennium. Parchment was not cheap – but opal for papyrus began not because of the emergence of a more profitable alternative but also from political processes in medieval Europe.

As a result, writing, preserving and reading documents has become expensive and affordable for a few, mainly monasteries, and the literacy rate among the standard population has dropped dramatically.

The revival of interest in ancient documents and papyri is associated already with the Renaissance period (when the paper was already in use). Still, only in the 18th century, when Herculaneum and Pompeii were freed from the ashes, the ancient scrolls became truly popular with researchers and readers.

The idea arose to revive papyrus production, but by that time, the plant itself was no longer cultivated in Egypt; it had to be brought from France. And the technology of making ancient papyri was restored experimentally in the second half of the last century.

Until the 11th century, the papyrus office used papyri, so there are plenty of papyrus scrolls in the halls of the Vatican’s library.